-

MANUFACTURING

Manufacturing from Art to Part

The ethics installed all those years ago still run true today, quality goods at competitive prices, the commitment and flexibility of our work force (of which most have been with us all of their working lives both old and new) giving the company a unique quality of experience and youth which blend seamlessly together, ensuring that over 50 years of expertise is passed down from generation to generation and finally onto you the customer.

Quality control is paramount at GUISELEY ENGINEERING and to this end we have invested heavily in our machine shop and drawing office, boasting some of the latest CNC machines and CAD/CAM technologies, this enables us to maintain the high standards customers have come to expect, all stages of the manufacturing process from draft drawing to the finished article are done on site, this gives us full control over materials and delivery.

-

TECHNOLOGY

Technology – State of the art factory

Guiseley Engineering has been at the fore front of technology ; our ability to adapt to change is a key factor in our continued success. Many of our skilled and loyal staff have been with Guiseley Engineering for most of their working lives and are a major factor in our success story, enabling us to continue to grow and stamp our mark on the Confectionery, packaging, machined spare Parts and components industry.

Our new premises has allowed for increased investment in new machinery and staff development, which will maintain the continued success that has been evident for the past half century. This will lead to the introduction of a new range of products and services.

-

SWEET SUCCESS

Sweet Success – Die Specialists

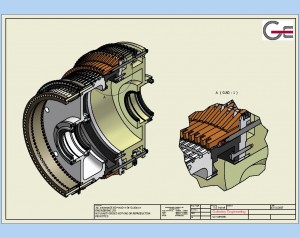

We Manufacture a number of different Rotary dies compatible with a large range of different machines, from our roots manufacturing our CF2 Confectionery line to the present day we take pride in the quality of our products. We offer a vast and diverse range of sweets forms each and every mould is specific to our customer’s requirements. Using state of the art 3D Cad cam Software we are able to liaise with our customers throughout he design process , producing 3D Drawings ,Wax Samples and weight calculation, this coupled with a very quick turnaround on standard dies (usually 3-4 working weeks from approved drawing) we are able to meet the demands of the ever changing market.

-

SPARES

Spares – General – Dies – Packaging

Designed and built to the highest standards and manufactured in state-of-the-art own factory using only the best raw materials , cutting tools and tool room technology, giving you the piece of mind that every stage of the production process has been monitored for quality control to ensure that every finished product meets ours and yours exacting requirements.

-

REPAIRS

Repairs – Die Clinic

Once approval has been given we strip and replace the damaged parts (all of which are manufactured on site) Rebuild and test ensuring that it has been restored to as good a working condition as possible. This obviously has its limitations but we find that this is a great short term method which greatly reduces down times with dies returning to service much quicker, which in the long run saves you money.